Polypropylene Fiber

PP Microfiber for plastic crack resistance of concrete

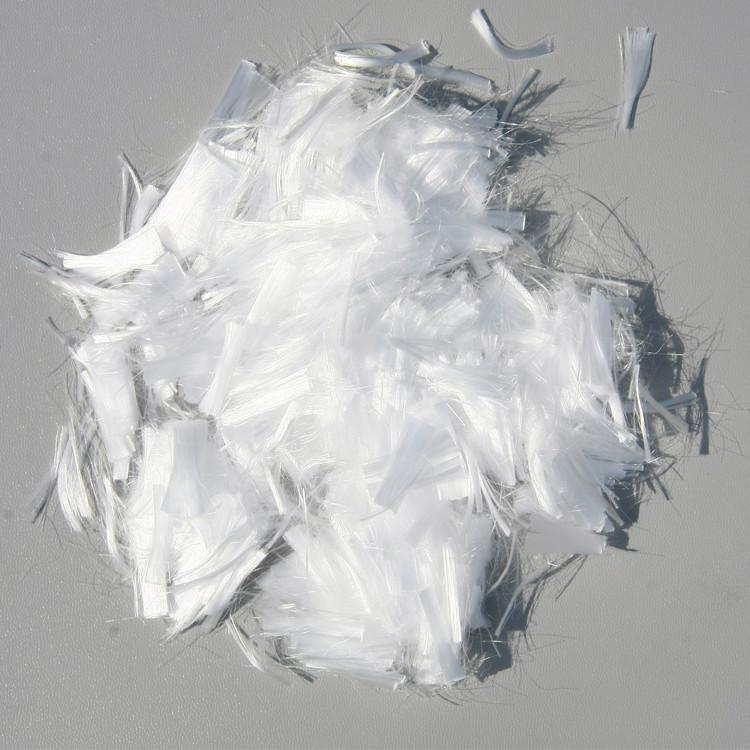

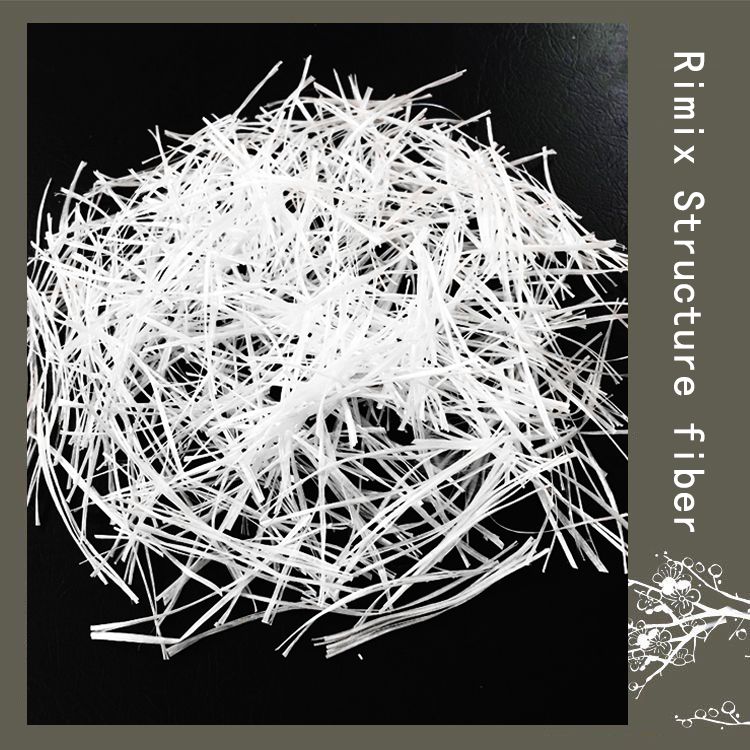

PP Microfiber is a kind of engineering short-cut fiber, which is mainly used to control the shrinkage of concrete in the plastic stage and reduce the risk of concrete cracking.

Polypropylene fiber

PP Microfiber for plastic crack resistance of concrete

Polypropylene fibre, also called PP microfiber, is a kind of engineering short-cut microfiber. PP fiber is used to produce fiber reinforced concrete to control the shrinkage of cement

concrete in the plastic stage and reduce the risk of concrete cracking.

Technological advantage

■ Excellent dispersion, the reinforcement fiber may made polypropylene fiber concrete with good dispersion.

■ Excellent crack resistance, plastic crack reduction coefficient more than 70%

■ Smaller fiber diameter, the same weight can provide more fiber.

■ The lower the content, the better the anti-crack effect.

■ Soft and balanced, no mark on the surface.

■ Acid resistance, alkali resistance and corrosion resistance.

■ Safe and easy to operate.

Packaging mode

PP Microfiber is packed in colored plastic bags, containing independent small packages, the weight of which is 600g/ bag or 900g/ bag or sub-packages according to the actual needs of customers or recommended fiber concrete mix.

Technical parameters

|

Fiber type |

Bundle monofilament |

Density |

0.91g/cm3 |

|

Diameter |

20-35μm |

Length |

12/19mm |

|

Tensile strength |

300-450MPa |

Elastic modulus |

3000-3500MPa |

|

Elongation at break |

≥15% |

Acid and alkali resistance |

Excellent |

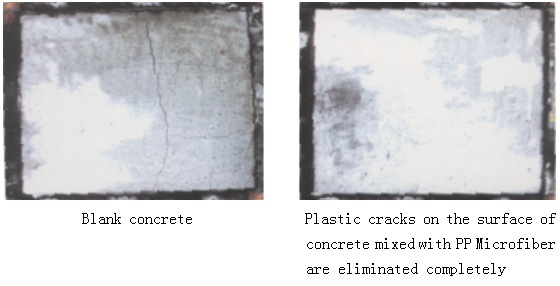

Crack resistance test

The anti-cracking effect of PP Microfiber is remarkable. The experimental results of the Engineering structure and material Test Center of Southeast University show that the anti-cracking grade of, PP Microfiber is the first grade (the best). The following are the experimental pictures.

Use method

■ PP Microfiber can be added in the concrete mixing station, and the mixing time should be extended appropriately to make the fiber disperse evenly.

■ For anti-plastic shrinkage cracking, it is recommended to add 600g per cubic meter of concrete.

Packaging mode

PP Microfiber is packed in colored plastic bags, containing independent small packages, the weight of which is 600g/ bag or 900g/ bag or sub-packages according to the actual needs of customers.

Quality standard and certification

■ PP Microfiber production conforms to ISO9001 quality management certification system.

■ Pioneer fiber series products are not included in the list of dangerous goods stipulated by 1272/2008/EC.

Matters needing attention

■ The plastic bag should not be fed directly, the package should be unpacked first, and then the fiber should be poured into the blender.

■ PP Microfiber is completely physical in concrete and does not change the original mix ratio of concrete.

Previous: No more

Next: Hollow PP Fiber